Discover the benefits of LTO technology

Unique batteries that still have 99% of their original capacity after more than 40,000 charging cycles and 6 years of operation! Let’s find more about LTO technology in this article.

Experience from sweden show that electromobilty can really work

In connection with electric cars and used accumulators, the most monitored parameter is usually the range of the vehicle on a single charge. It’s understandable – a driver always wants to reach their destination, even when using electric heating or air conditioning. If electric cars are to be replaced in the future by vehicles with internal combustion engines, they cannot fundamentally restrict drivers from an operational point of view.

From the point of view of the overall service life of the electric car and used accumulators, the number of charging cycles that the batteries are able to handle in often demanding climatic conditions is an equally important parameter. End of life is usually considered to be in situations where the maximum capacity of the battery at full charge reaches 80% of the original capacity. There are large differences between accumulators not only when comparing parameters such as specific energy density, specific power or requirements for operating temperature range, but also in terms of the maximum number of charging cycles. The differences are considerably large, while some accumulator technologies allow only a few units of a thousand cycles, and for the technology called LTO (lithium-titanate oxide) this can be many tens of thousands of charging cycles. This can be a particularly interesting solution, especially for purely urban electric cars, electric distribution vehicles (postal, transport companies, etc.) from an economic point of view when evaluating the total costs during the life of a vehicle. This is especially advantageous in situations without a requirement for a large range on a single charge and with the possibility of repeated charging even during a single day.

Experience in Schweden

The Swedish city of Umeå, located about 400 km from the Arctic Circle, has about 130,000 inhabitants, of which more than 50,000 are students. Thanks to the geographical location of the city, the average annual temperature ranges from – 0.8°C to + 6.7°C, the minimum temperature was measured at – 42°C (similar climatic conditions are, for example, in Šumava in the Kvilda area, i.e. at an altitude above 1,000 m above sea level). These are clearly demanding conditions for the operation of electric vehicles.

Since 2013, there have been 7 electric buses in operation in the city (5 twelve-metre and 2 eighteen-metre articulated), which were supplied to the local transport company by the company HYBRICON. An interesting feature of these electric buses is, amongst other things, that not only in production, but also in the development itself, the Ostrava company EKOVA Electric played a significant role, where the electric buses were also manufactured and subsequently transported to the city of Umeå.

The eighteen-metre articulated electric buses have both rear axles, with a total power of 600kW. This is a solution where there are two electric motors on each axle, each with an output of 125kW and a torque on the wheel of 11,000Nm. This guarantees excellent traction and driving dynamics even in poor adhesion conditions.

The accumulators are continuously recharged during the day each time the vehicle is at it’s final destination. On average, it’s about 20 recharges a day, 350 days a year, which is approximately 7,000 charging cycles per year. It is clear that in this case it was necessary to use high-cycle accumulators with LTO technology and the possibility of fast charging, so that after the first year of operation, the batteries reach the end of their life. Thanks to the possibility of frequent charging with a current of up to 1000A during the day, the accumulators could also be proportioned for a much shorter range (ranging between 20 and 25 km). The total capacity of the batteries is 78kWh, so in normal mode, with an average consumption of 1.3 to 2.2kW/km (real data from operation, the actual traction consumption without additional equipment such as heating or air conditioning is 0.98kWh/km) less than half of the total capacity between charging. This also has a positive effect on the service life of LTO accumulators, because with a relatively small discharge depth, the service life increases significantly, which has also been confirmed in Sweden.

Another interesting feature of these electric buses is the backup power source required by the customer for the so-called emergency mode. Each vehicle is equipped with a small diesel engine, which is not used in normal operation and would be activated only when the remaining accumulator capacity drops below 10% in an emergency, such as if a vehicle would remain in a blizzard for a long time, etc.

Batteries with a lifespan of several decades

Seven HYBRICON Arctic Whisper electric buses have traveled more than 1,100,000 km in Umeå in 6 years of operation, with 18 hours of operation every day. Thanks to remote monitoring of vehicles and monitoring of operating parameters such as electricity consumption, technical condition of accumulators, temperature of individual cells, discharge mode, etc. valuable data have been obtained which show that, with the correct vehicle concept and operation by the carrier, electric vehicles can be extremely beneficial, even from an economic point of view.

Each electric bus has already driven an average of 168,000km in Umeå and the accumulators show approximately 42,000 charging cycles, and these values are constantly increasing due to daily operation. At the same time, the total capacity has so far decreased by only 1%. Such a great result after 6 years of operation was achieved, among other things, because the thermal management of battery boxes was properly designed and there was no overheating of individual cells, which would otherwise significantly reduce the service life and accelerate a decline in maximum capacity. Another important parameter influencing the service life of accumulators is that discharging takes place under optimal conditions only in the range of 90-70% of capacity (for the articulated variant it is 90-60%). In addition, statistics on bus occupancy in Umeå showed that, following the deployment of electric buses in 2013, there was an increase long-term by 60% of passengers compared to diesel buses.

LTO battery cells

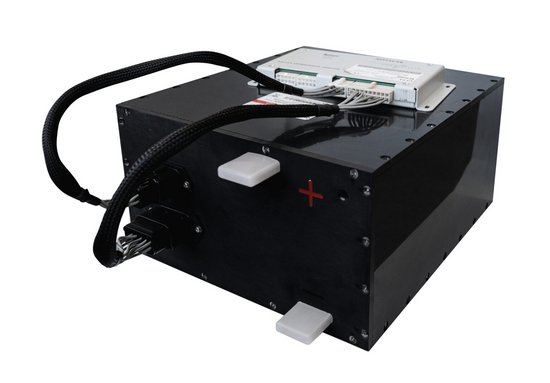

An integral part of each electric bus are two battery boxes, each consisting of twenty – eight 24V 60Ah modules from the American manufacturer AltairNano and equipped with water cooling. Liquid cooling ensures an even temperature throughout the box and is on average around + 30°C in each cell. If temperatures were significantly higher in some cells, e.g. above 50°C, this would have an extremely negative effect on the life of the entire battery box.

The manufacturer of the battery cells guarantees at a temperature of +25°C, a discharging or charging current maximum at double its capacity and 100% utilisation of all capacity (100% DOD) with a lifetime minimum of 16,000 cycles reaching 80% of original capacity. At the same time, operational experience has shown that a much longer service life can be achieved by reducing the use of the total battery capacity (DOD – depth of discharge parameter). For projects where battery capacity can be oversized and, amongst other things, a higher weight is acceptable, this solution seems very advantageous when evaluating the total operating time of an electric vehicle.

Find more about 24V 70Ah LTO battery module here

Können LTO-Batterien im eigenen Elektro-Auto verwendet werden?

Wenn die LTO-Technologie eine so wunderbare Batterielebensdauer ermöglicht, warum hat sie sich dann nicht in privaten Elektroautos durchgesetzt? Zunächst einmal stehen diesem Einsatz das höhere spezifische Gewicht pro 1 kWh Kapazität und der Stückpreis pro kWh entgegen, sodass eine solche Lösung angesichts der Nachfrage nach großer Reichweite bei Elektrofahrzeugen und begrenztem Einbauvolumen nicht sinnvoll ist. Vor allem, wenn der Hauptparameter die Reichweite pro Ladung und nicht die Gesamtzahl der Entladezyklen ist.

Die Situation kann sich jedoch drastisch ändern, wenn das Elektrofahrzeug ausschließlich in der Stadt eingesetzt werden soll, idealerweise auf wiederkehrenden Strecken mit regelmäßiger Rückkehr, z.B. in der Stadt zum Hauptsitz eines Lieferunternehmens, und insbesondere, wenn der Betreiber beim Kauf des Elektrofahrzeugs nicht nur die Anschaffungskosten, sondern auch die Gesamtkosten über die Lebensdauer des Fahrzeugs bewertet. In diesem Fall haben LTO-Batterien eine echte Chance, in der Elektromobilität für den Privatgebrauch, einschließlich verschiedener Vans oder kleiner städtischer E-Mietwagen usw., in größerem Umfang eingesetzt zu werden, da die Batterien z.B. nicht nach 5 Jahren durch neue ersetzt werden müssen.