Fast-charging

In this article, we will find out what technologies are suitable for fast-charging and what advantages LTO battery technology has for this sector also from an economic perspective. We will skip the segment of passenger cars, long-distance buses, and lorries. There is a focus on the long driving range between two charging stations without a stop. An excellent example of fast-charging is the segment of city e-buses with regular stops, returns to terminal stations, and the driver’s pauses given by the public transport schedule. These downtimes may be utilized for fast-charging. Therefore, the option of fast-charging has been introduced and one can benefit from its economic advantages. But let’s start from the very beginning.

The list of abbreviations and terminology is at the bottom of the article.

Technology

Thanks to the development in the area of batteries (energetic storages), there are alternatives to the operation of electric vehicles. Fast-charging is one of the options. Within a short period of time, you are able to charge the battery with high power without any extreme heating of the battery system and thus decreasing its cyclic and calendar lifespan.

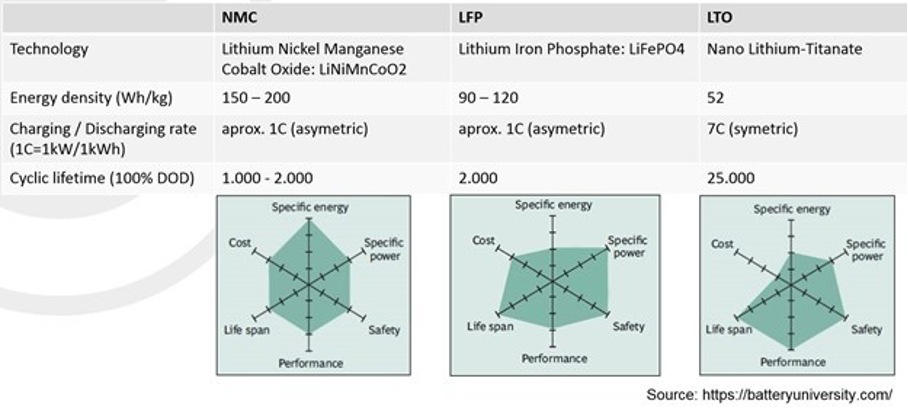

LTO batteries are currently the most suitable for fast charging (the best ones have a life span of 25.000 – 39.000 cycles at 80% DOD). This is high-power technology (HP). Fast-charging can be also performed with the currently most widespread technology of NMC or LFP batteries. These technologies are called high-energy (HE). One of the disadvantages is the necessity of a huge capacity battery in the vehicle and from which only a minor part is used for charging (e.g. 30 % from 400 kWh) to avoid the overheating and thereby reducing the battery life. From NMC and LFP (LiFePo4) technologies we can get about 2.000 – 5.000 cycles at 80% DOD which is at least five times lower lifespan than in the case of LTO batteries.

Electric city buses

Fast-charging is currently the most widespread in the operation of city buses. The great fit of this option is thanks to the possibility of the charging infrastructure deployment and the need for only shorter driving ranges needed for a single charging (comparing to the option of depo/slow charging with high-energy batteries/long-range lasting capacities). Generally, the fast-charging is based on vehicles operating by traction batteries charged with high performance (approximate 200 – 800 kW). It can be done on their track, at stops, or terminal stations only. This principle can be called opportunity-charging (note: it is the fast-charging in the downtimes of the application). This principle enables the following advantages (in compare to HE batteries):

- Permanent operation of the vehicle – 24/7 (it doesn’t need to be charged for hours),

- Multiple increases of the battery’s lifespan,

- Effective recuperation during the braking (LTO can absorb more power),

- Operation of HP battery with the temperature below zero without any additional heaters (from -50°C),

- Fewer requirements for the charging infrastructure at depo since the vehicles are gradually charged on the way,

- The decrease in the total costs of the ownership (TCO) and operational costs (compared to the diesel the operational cost can be lowered to only one third – 1/3) when all aspects are set up properly.

Of course, you may object that there are higher requirements for the city charging infrastructure and reserved supplied power from the electricity network. The selection of the principle of functioning of electric buses in the city traffic should be in the early phases accompanied by the analysis with careful calculations. Cities with the established tram and trolleybus networks have it easier. The reason behind this is the access to sufficient power wattage from the network in the routes.

A practical calculation example of the size of the battery may be, for instance, a 40km route across the city and back. With the approximate (winter) consumption of 1.6 kWh/km, we may easily calculate 64 kWh for a distance route. Since we do not want to fully discharge the battery (meaning 100 % DOD or 0 % SOC), we increase the capacity to 80 kWh. With this battery capacity, a fast-charger will be sufficient for us only at one terminal station. With the performance of 560 kW, it is charged within 7 minutes and the bus may nicely start another journey. The infrastructure along the way may vary. It can be easily counted that with additional fast-chargers on the way, with higher or smaller battery capacities, we may reach any values and optimize the operation of the city transport.

There have been a lot of new implementations and inspirations across Europe recently. For instance, MZK in the town Zielona Gora in Poland has declared a 60 % electrified fleet.

Partial trolleybuses and trams

Trolleybuses and trams can be considered as interesting electric vehicles. Why should it have a battery if they are all the time charged by the trolley? The main reason is the ever-expanding cities. Mainly for trolleybuses, with additional battery, we may easily reach prolongation of lines to more distant parts of the cities, suburban areas as well as villages without the need to build trolleys. In the case of trams, it may be either the impossibility to locate the trolley line (overhead contact line) to the monument protected historical areas or the insufficient performance of the network. Once the vehicle gets back under the trolley, the battery starts charging again.

Another reason is the efficient energy recovery during braking (recuperation) and thus the reduction of operating energy costs. Earlier, super-capacities were utilized for recuperation; they are, however, pushed out by LTO batteries due to their sufficient performance and higher capacity.

It is a very good solution for cities with already established infrastructure. Partial trolleybuses may be seen in numerous cities around Europe. Partial trolleybuses can be seen in several Czech cities, such as Pardubice, Pilsen, Brno, Zlin, Teplice, Hradec Kralove, Ceske Budejovice, Prague, Marianske Lazne, Ostrava, Opava, Usti nad Labem.

Port facilities (vehicles and travelling cranes)

Another sector where electrification is currently taking place is container transshipment. The container handling equipment as a shuttle and straddle carrier, AGV, RTG (rubber tire gantry), etc is turning into the electric or hybrid variants.

The company Kalmar is worth mentioning since they got an award by the PEMA association for innovative and cutting-the-edge development in the industry. With its fast-charging system called Kalmar FastCharge™, they amazed the jury among 21 participating companies. Within the option FastCharge™, Kalmar offers AGV (automated guided vehicles), Shuttle carriers, and Straddle carriers. Vehicles are equipped with LTO battery systems. Charging of vehicles is performed during their downtimes.

Comparing to diesel vehicles, electrification offers:

- Decrease of local emissions to zero, better atmosphere for drivers in the cabin,

- Decrease of noise, vibrations, and heat generation,

- Better driver’s control over the vehicle – meaning the following

- smoother acceleration,

- higher performance,

- Elimination of long downtimes in order to switch spare batteries (lead-acid).

Since charging can be conducted on the route of the vehicle as a natural part of the operational process, one gain benefit from faster turns and risen productivity whereas availability of the machine is up to 90 % of the time.

Comparing to diesel vehicles and cranes, the electric ones, apart from decreasing local emissions, also significantly reduce the operational costs (on average the costs are cut by half)!

Other Industries

The practice has already shown that fast-charging electrification has economic benefits in addition to improving the local environment. We can also mention other sectors for which this form of electrification has undoubted economic reasons. These are, in particular, the areas where vehicles and machines move within a determined area and may be charged more often which utilizes downtimes (e.g. for 8 minutes every 3 hours).

There is a big potential for the following fields:

- Airport facilities – in general, GSE (Ground Support Equipment). Namely, for instance, plane shunters (pushback, taxibot, towbarless tractor), conveyor belts, escalators);

- Construction machines – diggers, cranes;

- Port ships – ferries, tugboats;

- Warehouse vehicles – e.g. AGV, forklifts.

Finally, bellow is a summary of the advantages gained by fast-charging:

- High performance via a small battery capacity (often without the use of A/C),

- Increase in battery lifespan (similar to the lifespan of the vehicle itself),

- Decrease in total cost of ownership (TCO),

- Increase in vehicle’s productivity – charging on the route during idle times, operation 24/7.

Conclusion

In general, it can be said that the development of electrification across sectors was led through high-energy batteries (lead, NMC, LFP). For many vehicle operators, the longest possible range has been a top priority in the past. This was due to the fact that the battery systems technologies weren’t sufficient for fast-charging (LTO). Thanks to current technological advances, we can say that in the above-mentioned industries, fast-charging batteries make operational and economic sense. That the reason why GREAT development is expected here.

It will be interesting to observe which industries will become the cutting-the-edge area and will be electrified via fast-charge technologies. There is no doubt that we won’t need to wait for it a long time.

Terminology and abbreviations:

- High-energy, NMC (Lithium Nickel Manganese Cobalt), LFP (Lithium Iron Phosphate)

- High-power, LTO (Lithium Titanate)

- Forms of electrification:

- Fast-charging

- Opportunity charging

- Depot-charging (slow charging)

- DOD depth of discharge

- SOC state of charge

- PEMA Port equipment manufacturers association

- TCO total cost of ownership

Resources:

https://www.kalmarglobal.com/equipment-services/straddle-carriers/fastcharge-straddle/